What Are Epoxy Prepregs?

Definition and Composition

Epoxy prepregs are composite materials that consist of reinforcement fibers pre-impregnated with a partially cured epoxy resin. This combination provides enhanced structural integrity and allows for various manufacturing techniques to be utilized in their production. The reinforcements, typically made of carbon fiber, fiberglass, or aramid, are saturated with epoxy resins that provide excellent adhesion, strength, and durability. The pre-impregnation helps to control the resin content, ensuring a consistent and uniform distribution of the resin throughout the fibers, which is critical for the performance of the final composite product. For more detailed exploration into the characteristics and types of epoxy prepregs, you can check out the epoxy prepregs sections available in various industry resources.

Types of Epoxy Prepregs

Epoxy prepregs are categorized based on different factors, including fiber type, resin formulation, and curing systems. The main types include:

- Carbon Fiber Epoxy Prepregs: Known for their superior strength-to-weight ratio, these prepregs are ideal for high-performance applications in aerospace and automotive fields.

- Fiberglass Epoxy Prepregs: More affordable than carbon fiber, these prepregs offer good performance and are widely used in construction and automotive industries.

- Aramid Fiber Epoxy Prepregs: These provide excellent impact resistance and are typically utilized in aerospace and military applications.

- Specialized Epoxy Prepregs: Tailored for specific applications, such as high-temperature or fire-resistant environments, these prepregs are formulated to meet unique requirements.

Key Properties and Characteristics

The key properties of epoxy prepregs that make them highly sought after in advanced manufacturing contexts include:

- High Strength and Stiffness: They exhibit significant tensile strength allowing for the creation of lightweight structures without compromising durability.

- Thermal Resistance: Depending on the formulation, these prepregs can withstand high temperatures, making them suitable for specialized applications.

- Reduced Cure Time: The semi-cured state of prepregs allows for faster processing times compared to traditional wet layup methods, enhancing manufacturing efficiency.

- Low Shrinkage: Minimal dimensional changes upon curing ensures high fidelity in the final composite component.

Applications of Epoxy Prepregs Across Industries

Aerospace and Defense Utilization

In the aerospace sector, epoxy prepregs are indispensable in manufacturing aircraft wings, fuselages, and other critical components. Their lightweight yet robust nature leads to significant fuel efficiency and performance improvement. For defense applications, the ability to tailor these materials for high fatigue resistance and environmental resilience is crucial, especially considering the rigorous conditions these components face.

Automotive Sector Innovations

The automotive industry has increasingly adopted epoxy prepregs to manufacture lightweight parts that contribute to fuel efficiency and reduced emissions. The integration of these materials leads to advanced manufacturing techniques such as automated fiber placement (AFP) and robotic layup, enabling complex geometries that were once challenging to produce with traditional methods. The focus on electric vehicles has also increased demand for components that combine strength with minimal weight.

Sports Equipment Manufacturing

In sports equipment, epoxy prepregs play a vital role in product innovation. From bicycles and fishing rods to skis and surfboards, the goal is to enhance performance while maintaining durability. Manufacturers leverage the high tensile strength of epoxy prepregs to create stiff yet responsive equipment that meets the demands of professional athletes and casual users alike.

Processing Techniques for Epoxy Prepregs

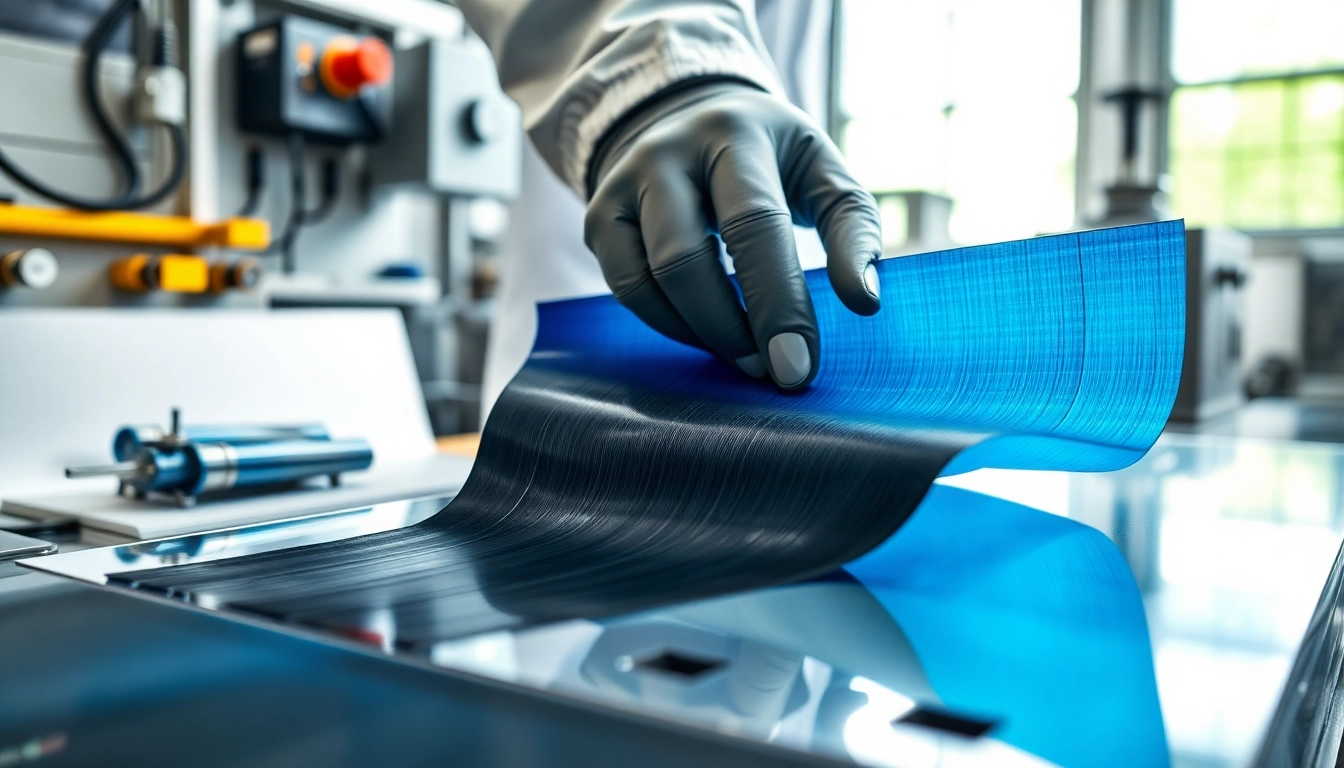

Preparation and Handling Guidelines

Proper handling of epoxy prepregs is crucial to maintain their performance attributes. They should be stored at low temperatures to prevent premature curing. When ready for processing, they need to be allowed to reach ambient temperature before use to ensure optimal flow characteristics during the layup process. Precise cuts and handling methods can optimize yield and minimize waste.

Curing Methods Explained

Curing of epoxy prepregs can be achieved through various methods, primarily thermal curing, where heat is used to fully polymerize the resin. The required conditions depend on the resin formulation, and it’s essential to monitor the curing environment’s temperature and humidity carefully. There are also thermoplastically cured prepregs, which allow for re-processing, offering greater design flexibility and repairability.

Cutting and Layup Processes

The cutting of epoxy prepregs demands precision to ensure that the right amount of material is used without wastage. Techniques include laser cutting and traditional manual cutting, with the former providing higher accuracy. During the layup process, automation is increasingly being utilized through computerized systems that can place layers precisely according to the design specifications, enhancing consistency and product quality.

Advantages of Using Epoxy Prepregs

Performance Benefits Compared to Traditional Methods

Epoxy prepregs significantly improve the mechanical properties of composite materials compared to traditional wet layup methods. The controlled resin-to-fiber ratio achieved through prepreg manufacturing leads to superior strength and reduced void content, which often compromises composite performance in traditional methods. Automated processes also enable greater precision and repeatability, reducing variability in production.

Cost Efficiency Over Time

While the initial cost of epoxy prepregs can be higher than traditional materials, long-term savings are achieved through reduced waste, shorter processing times, and enhanced durability. Their resistance to environmental factors also results in lower maintenance and repair costs over the lifecycle of the components manufactured from these materials.

Environmental Considerations

Epoxy prepregs contribute positively to sustainability efforts in manufacturing. The lightweight nature of composite components leads to improved energy efficiency in products like vehicles and aircraft, which translates to lower carbon emissions. Additionally, many manufacturers are working towards recyclable resin systems, thereby reducing the environmental impact of discarded materials.

Challenges and Solutions in Working with Epoxy Prepregs

Common Manufacturing Challenges

Despite their benefits, working with epoxy prepregs poses challenges such as sensitivity to moisture, which can affect curing quality and final part performance. Furthermore, the need for precise storage conditions complicates handling practices. The high cost of the materials can also be a barrier for some manufacturers.

Technical Innovations Addressing Issues

Innovations in material science are being developed to address these challenges. For instance, moisture-resistant formulations are being created, and advancements in storage solutions like vacuum-sealed packaging help prolong shelf life and maintain performance. Additionally, new automated manufacturing techniques contribute to improved efficiency and consistency.

Best Practices for Optimal Results

To get the best results from epoxy prepregs, manufacturers should adhere to best practices such as maintaining rigorous quality control throughout the production process, investing in staff training for proper handling and processing techniques, and collaborating with suppliers for improved material formulations. Using modern manufacturing technologies like digital twins and advanced analytics can further enhance production quality and yield.