Introduction to HPMC Factory Processes

Hydroxypropyl Methylcellulose (HPMC) is a versatile compound used across various industries, garnering attention due to its unique properties. Understanding the processes involved in HPMC production at a dedicated HPMC factory can provide insight into how this crucial material is made and its significance in modern applications. From construction to pharmaceuticals, HPMC plays a critical role, and its manufacturing processes are equally important as the product itself.

What is Hydroxypropyl Methylcellulose?

Hydroxypropyl Methylcellulose is a cellulose derivative, created by chemically modifying cellulose, a natural polymer derived from plant fibers. This modification enables HPMC to inherit unique properties, such as water solubility, film-forming capabilities, and thickening characteristics, making it a sought-after ingredient across multiple sectors.

Importance of HPMC in Various Industries

HPMC has found extensive use in various industries due to its multifunctionality. In construction, it’s used as a crucial additive in cement and mortar mixes to enhance workability and stability. In the food industry, it acts as a thickener and emulsifier, improving the texture and consistency of products like sauces and dairy. Moreover, in pharmaceuticals, HPMC is utilized as an excipient in drug formulations, providing controlled release of active ingredients. The broad applicability of HPMC underscores its importance in advancing industry standards and improving product quality.

Overview of HPMC Factory Operations

The operations within an HPMC factory are systematically designed to ensure efficient production while adhering to the highest quality standards. From sourcing raw materials to developing end products, each step plays a vital role in determining the overall effectiveness and reliability of the HPMC produced. Quality management and safety protocols are integral aspects, ensuring that the processes not only meet industry demands but also comply with regulatory compliance.

Key Production Methods in HPMC Factories

Raw Material Sourcing for HPMC

The production of HPMC begins with the careful selection of raw materials. The primary component is cellulose, which can be sourced from various plant materials. The quality of cellulose directly influences the final properties of HPMC, making it imperative to establish strong relationships with reliable suppliers. Sustainable sourcing practices are increasingly adopted, focusing on environmentally friendly forestry and cultivation methods to ensure that raw materials are replenished.

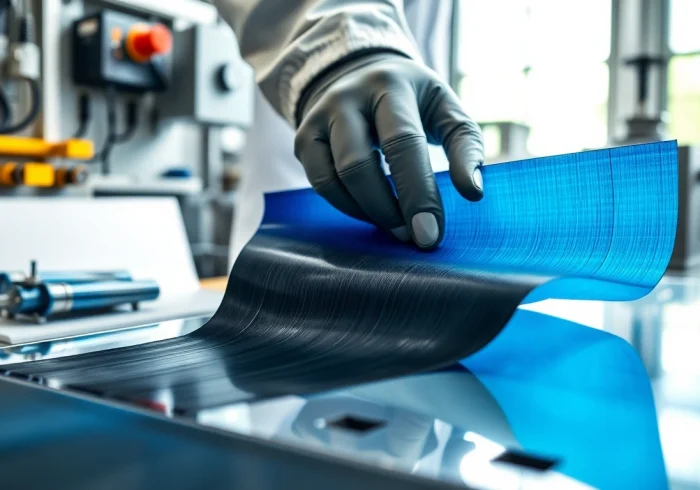

Manufacturing Techniques Explained

The manufacturing process of HPMC involves several critical steps, primarily involving the etherification of cellulose. First, cellulose pulp is treated with propylene oxide and methyl chloride in a controlled environment to produce hydroxypropyl and methyl ether groups. This chemical transformation results in a highly soluble product that retains excellent emulsification properties. The degree of substitution—determining how many of the hydroxyl groups in cellulose are substituted—affects the physical properties of the HPMC, tailoring it to specific applications. Subsequent purification, drying, and milling processes refine the product to meet precise industry specifications.

Quality Control Measures in HPMC Production

Quality control in HPMC production is paramount to guarantee product integrity and compliance with industry regulations. Factories implement rigorous testing at multiple stages of manufacturing, assessing key characteristics such as viscosity, gel formation, and solubility. Advanced analytical techniques, including chromatography and spectroscopy, are employed to ensure that the end product meets specified standards and performs reliably in its intended applications. Factory environments are also monitored for contamination risks, with regular audits and certifications reinforcing safety protocols.

Applications of HPMC from Factories

Use of HPMC in Construction

In the construction industry, HPMC serves as an essential additive in cement-based products, such as tile adhesives and drywall compounds. Its ability to retain water enhances the performance of these materials, allowing for extended workability times without compromising strength. As a cellulose ether, HPMC aids in improving the structural integrity of complex building materials, resulting in increased durability and resilience against environmental factors.

How HPMC Enhances Food Products

HPMC is prominent in the food industry for its thickening, binding, and emulsifying properties. It is commonly found in various food products such as sauces, dressings, ice creams, and baked goods. Its non-toxic and stable nature makes it an ideal ingredient for creating desired textures without altering flavors. Additionally, HPMC acts as a stabilizer in gluten-free baking, allowing for improved texture and moisture retention.

Role of HPMC in Pharmaceutical Industries

In pharmaceuticals, HPMC is pivotal as an excipient in optimization formulations, particularly in controlled-release drugs. Its ability to form gels in the gastrointestinal tract allows for the sustained release of active ingredients, improving therapeutic efficacy. Moreover, HPMC is also employed as a binder in the tablet formulation side of things, contributing to the overall mechanical stability and integrity of medication tablets.

Challenges in HPMC Factory Operations

Managing Quality and Consistency

Ensuring product quality and consistency poses significant challenges in HPMC factory operations. Variation in raw material quality, production techniques, and environmental conditions can all affect the end product’s characteristics. Implementing standardized operating procedures (SOPs) and investing in state-of-the-art analytical equipment can help manufacturers maintain high-quality outputs. Continuous training for staff on quality management practices is also essential to mitigate risks associated with inconsistencies.

Environmental Considerations and Compliance

As with any industrial operation, HPMC factories must navigate environmental considerations and regulatory compliance. Waste management, emissions, and sustainable practices are crucial to ensuring environmentally friendly production. Many factories are adopting eco-friendly technologies and processes that minimize their carbon footprint and comply with international environmental standards.

Supply Chain Challenges in HPMC Production

Supply chain management is another critical area of focus for HPMC factories. Fluctuations in raw material availability, price volatility, and transportation issues can disrupt the entire production process. Establishing strong relationships with suppliers, incorporating flexible production schedules, and utilizing advanced logistics solutions can help mitigate these challenges and result in a more resilient supply chain.

Future Trends in HPMC Manufacturing

Innovation and Technology in HPMC Factories

The future of HPMC manufacturing is poised for innovation, with advancements in technology reshaping production methodologies. Automation and Industry 4.0 technologies are being integrated into HPMC factories to enhance productivity, efficiency, and accuracy. These innovations include intelligent manufacturing systems that utilize real-time data analytics to optimize processes and reduce downtime, ensuring a more agile production environment.

Sustainable Practices and Eco-Friendly Solutions

As environmental concerns rise, adopting sustainable practices in HPMC production will become increasingly important. This includes using renewable resources, reducing energy consumption, and implementing waste management techniques that promote recycling and waste reduction. The adoption of biodegradable alternatives to traditional HPMC may also drive future product development as consumer demand shifts towards eco-friendly materials.

The Global Market Outlook for HPMC

The global market for HPMC is projected to expand significantly, driven by growing demand in construction, food, and pharmaceuticals. As industries seek more versatile and efficient materials, the adaptability of HPMC positions it well for continued growth. Market dynamics will often reflect broader trends in global economic conditions, where innovations in applications and manufacturing techniques are likely to give competitive advantages to early adopters.