1. Introduction to Machine Vision

In an increasingly automated world, machine vision stands at the forefront, revolutionizing industries by enabling machines to interpret visual data in ways previously unimaginable. This technology encompasses the use of cameras, sensors, and software algorithms, acting like the visual system of a human being but with far greater precision and speed. Understanding machine vision’s components, functionality, and impact is vital for industries ranging from manufacturing to healthcare, where visual inspections and data categorization are integral to quality control processes.

1.1 What is Machine Vision?

Machine vision is the technology that enables machines or computers to interpret and process images from the real world, mimicking the human ability to see but applying it to automated systems. It employs one or more cameras to capture imagery, which is then converted into digital data for analysis by various algorithms. This technology is essential for tasks such as object recognition, inspection, and process automation, enhancing efficiency and accuracy beyond human capabilities.

1.2 Key Components of Machine Vision Systems

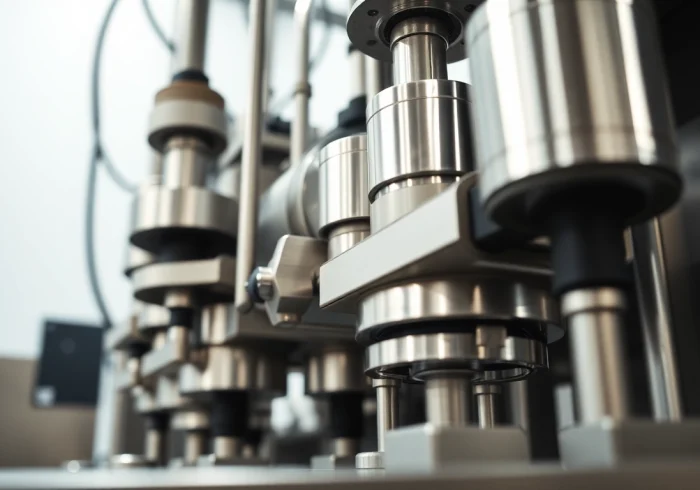

Machine vision systems are generally composed of several key components:

- Imaging Devices: Cameras equipped with high-resolution sensors that capture images in various lighting conditions.

- Illumination: Proper lighting techniques, such as LED technology, enhance image quality by controlling shadows and highlights.

- Computer Processing: Software systems, including image processing algorithms and computers (or edge devices), that analyze the captured images to extract meaningful data.

- Communication Interfaces: These interfaces connect machine vision systems with other production systems, allowing data transfer and operational integration.

1.3 The Importance of Machine Vision in Industry

The implementation of machine vision technologies offers numerous advantages, making it a critical component in modern manufacturing and quality assurance processes. For industries producing large volumes of products, the ability to detect defects during manufacturing can substantially reduce waste and rework costs. Furthermore, with the increasingly competitive landscape, businesses leverage machine vision to enhance product quality and streamline operations.

2. Applications of Machine Vision

The versatility of machine vision allows for a plethora of applications across various industries, demonstrating its capability to enhance operational efficiency and quality control.

2.1 Machine Vision in Quality Control

One of the most crucial applications of machine vision is in quality control. By integrating machine vision systems into production lines, companies can automate inspections to assess product quality in real time. Early detection of defects not only prevents subpar products from reaching consumers but also minimizes recalls and damage to brand reputation. For example, in the electronics industry, machine vision is utilized to verify components on circuit boards, ensuring each component is correctly placed and fully functional.

2.2 Automating Inspection Processes

Machine vision simplifies and enhances inspection processes across different manufacturing stages. Automated inspection using machine vision can scan for specific dimensions, colors, or markings with unrivaled precision. Manufacturers employing this technology are able to replace manual inspection processes that are often slow, inconsistent, and reliant on human judgment, thereby boosting both operational speed and accuracy. The automotive industry, for example, uses machine vision systems to monitor assembly processes, ensuring every bolt and component adheres to safety standards.

2.3 Case Studies of Machine Vision Implementation

Numerous industries have successfully implemented machine vision technologies, leading to significant improvements in productivity and quality. For instance, a well-known beverage manufacturer recently adopted a machine vision system to monitor the fill levels of bottles on its production line. The system successfully detected fill errors in real time, thereby reducing waste and operational disruptions. In another case, a pharmaceutical company utilized machine vision to ensure accurate labeling and packaging, greatly minimizing the risk of medication errors.

3. Advantages of Using Machine Vision

Machine vision is not just a trendy technology; it brings measurable benefits that enhance operational outcomes across various sectors.

3.1 Increased Efficiency and Accuracy

One of the primary advantages of machine vision is its ability to work tirelessly at a speed far superior to human capability. It can process thousands of images per minute, ensuring rapid analysis and decision-making. In addition to speed, machine vision improves accuracy significantly, reducing the instances of human error during inspections. Industries that have adopted this technology report a notable decrease in false positives and false negatives in quality assessments.

3.2 Cost Reduction in Manufacturing

The integration of machine vision leads to substantial cost savings by minimizing defective product rates and ensuring compliance with regulatory standards, thus avoiding fines and recalls. Automation of visual inspections allows companies to redirect human resources towards more complex tasks, further enhancing overall productivity. For example, manufacturers that employ automated quality checks have reported up to a 30% decrease in production costs over time.

3.3 Enhancing Product Quality Consistency

With machine vision systems in place, companies can achieve a remarkable level of consistency in product quality, which is essential for maintaining customer satisfaction and loyalty. Automated systems ensure each product adheres to quality standards without variance, enabling businesses to build a reputation for reliability. This consistency ensures that products meet the expectations of consumers in different markets, fostering trust and preference for a brand.

4. Challenges in Machine Vision

While the advantages of machine vision systems are undeniable, organizations may encounter several challenges during implementation and integration.

4.1 Technical Limitations and Solutions

One significant challenge in machine vision is the technical limitations associated with image acquisition and processing. Variability in lighting, material textures, and colors can affect outcome accuracy. Solutions lie in employing advanced image processing techniques, utilizing adaptive lighting strategies, and utilizing high-performance cameras suited for specific tasks to overcome these hurdles.

4.2 Integration with Existing Systems

Integrating machine vision into existing workflows can pose challenges, especially in legacy systems. Data compatibility and communication between new machine vision systems and established technology can complicate implementation. Adopting standardized communication protocols and ensuring thorough testing can ease this integration process, allowing for smoother transitions and optimal functionality.

4.3 Future Trends and Developments

The field of machine vision is continually evolving, with trends like AI and deep learning significantly enhancing capabilities. Future developments may focus on increasing camera resolution, simplifying setup processes, and employing cloud computing for data-heavy tasks. Such innovations will further enhance the efficiency and breadth of machine vision applications.

5. Conclusion: The Future of Machine Vision

Machine vision is undeniably transforming industries and setting new standards for automated processes. Its role in optimizing inspections, enhancing quality, and reducing costs paves the way for future growth and integration.

5.1 Innovations on the Horizon

As technology progresses, innovations such as smart cameras infused with AI capabilities promise to redefine how inspection processes occur. These advancements will further empower organizations to maximize productivity while minimizing errors, ensuring continuous improvement in industrial operations.

5.2 Machine Vision and Artificial Intelligence

The intersection of machine vision and artificial intelligence marks a significant leap for the industry. AI can enhance image recognition and decision-making capabilities, allowing for predictive maintenance and real-time monitoring. This synergy could lead to machines that learn and adapt, optimizing processes continually.

5.3 Final Thoughts on Machine Vision’s Impact

Understanding machine vision’s complexities and advantages enables organizations to harness its full potential, paving the way for innovation and excellence. As industries evolve, machine vision will play an integral role in maintaining competitiveness and operational efficiency, ushering in a new era of automated quality assurance.